ZINTEK® COMPOSITION

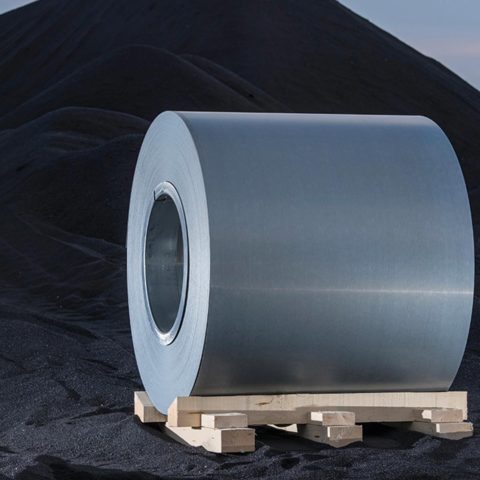

The alloy must be produced starting from 99,995% pure Z1-quality zinc, as set forth by European Standard EN 1179, with the addition of alloy elements.

From zinc to zintek®

from raw material to application

ZINC CRYSTALS

Zinc crystals compliant with European Standard EN 1179.

CASTING

Casting of zinc with alloy elements (copper and titanium).

NATURAL ZINTEK®

Natural zintek® is a glossy grey colour.

ROLLED PRODUCTS

The rolled products can be subjected to pre-coating procedures.

THE COLOR LINE

The Color Line, the new line of colored rolled products.

APPLICATIONS

zintek® is used for covering, façade and tinsmithery solutions.