The piers of the public transport water stops; the cupola of the Café Haus in the Royal Gardens of San Marco; the Molino Stucky, which imperiously overlooks the Giudecca Canal; or Murano, where Le Conterie were born to a new life, following a sustainable requalification intervention; the Cini Foundation, on the island of San Giorgio, which hosts the Vatican Chapels exhibit where the most important architects in the world expressed their art.

Surrounded by the Venetian canals, the common denominator of the places listed above is the presence of zintek®. Enveloped in a sort of crescendo of planning, protection and versatility, Zintek titanium zinc is a key protagonist in the requalification of the historical center of Venice.

In its conservation or requalification operations, as well as in its innovative projects, Zintek has proven its ability to read its city of birth, adapt to its rules and respect its customs and architectonic dictates, even going as far as expressing its international nature and futurist modernity, in a modern work such as the Vatican Chapel designed by the Australian architect Sean Godsell.

These are the topics we touched on in our interview with Renata Codello, General Secretary of the Giorgio Cini Foundation, former Superintendent for the Architectonic and Landscape Heritage of Venice and Director of the Regional Secretariat of the Ministry of Cultural Heritage and Activities for the Veneto Region. A renowned architect and among the most authoritative figures in our country, Renata Codello spoke to us about the conservation and protection of the architectonic heritage of Venice, suspended between past and future, lead and zintek®.

VIDEO INTERVIEW

Interview with Renata Codello

General Secretary of the Giorgio Cini Foundation

The wharf piers: zintek® as a harmonizing element between matter, light and movement

Zintek requalified the main wharf piers for the Venetian means of public transport. If we follow the Grand Canal, the stops featuring requalified piers are Piazzale Roma, Ferrovia, Rialto, Giardinetti, San Marco and, further down the Canal, the Lido. The urban mobility terminals can now count on approximately ten rebuilt landings, as well as the full renewal of all the ticket booths.

The contemporary nature of these locations is what makes them stand out as profoundly interesting from both an architectonic and functional point of view: the zintek® rolled products “design” a linear and simple structure that, thanks to its non-invasive color and opaque surface, marries aesthetic requirements with practical needs in terms of resistance against corrosion and durability.

The grey-colored titanium zinc is pleasantly amalgamated with the wood and glass, reflecting the light of the sky and playing with the movements of the water.

This project was designed by the architects Pierpaolo Fugali and Luca Gasparini, who chose to base their work on a historical suggestion: the wharfs are indeed inspired by a pier built on the Lido in the 1950s and designed by the architect Duilio Torres.

The relationship with the waterfront was solved by using large glazed surfaces to maintain visual permeability, while transparency and ease of movement are guaranteed by the opening of the front on the land side. Energy savings are ensured by the installation of photovoltaic systems.

Therefore, zintek® titanium zinc rolled products prove to be an ideal material for requalification projects, capable of guaranteeing a long lifespan for the construction, thanks to their resistance against humidity and their maintenance-free nature. These products are capable of combining the conformability needed to reproduce different styles and suggestions with a level of resistance that requires no further interventions, while at the same time perfectly blending into the surrounding environment.

A MATERIAL THAT RESPECTS WHAT ALREADY EXISTS

Excerpt from the interview with Renata Codello

General Secretary of the Giorgio Cini Foundation

Art returned to the city: zintek® is the heir to lead in the restoration of the Royal Gardens

The restoration of the Royal Gardens of San Marco proves how zintek® truly respects previous constructions. Adjacent to Piazza San Marco, the Royal Gardens are open to the public and extend over a surface of approximately 5,000 square meters.

zintek® was used for the roofing solutions of the buildings, in particular for the conservatory.

The material presents itself as the evolution and contemporary version of lead, thus offering a sort of continuity with the leaden cupola of the Pavilion built by Santi and many other Venetian cupolas.

Zintek proved to be the ideal partner for this project. The company’s titanium zinc rolled products were the best solution to meet ecological requirements, but also to satisfy landscape and formal aspects.

The zintek® titanium zinc plays a key role in this project, as a material of the future. It allows the ancient parts to dialogue with the new ones, harmoniously enters the surrounding environment and blends with pre-existing elements.

As seen from the basin of San Marco, the new conservatory, with its titanium zinc roof, appears to embrace the Café Haus in a completely natural way. The relationship with the shadows, colors and cupola is in itself a dialogue between the new and the ancient. The chromatic value of the titanium zinc is a founding element: it has the color of light, the color of lead, and a strong aesthetic value, as it accommodates light without resisting it.

LIKE LEAD, ZINTEK IS A TECHNOLOGICAL INTUITION

Excerpt from the interview with Renata Codello

General Secretary of the Giorgio Cini Foundation

Between the past and the present: the Molino Stucky as an example of dialogue between history and modernity

From the Grand Canal, we now move to the Giudecca canal. An industrial architecture from the nineteenth century transformed into a 5-star hotel, the Molino Stucky required extraordinary attention and a careful selection of materials, to avoid betraying the unique nature of a building that marked both the history and look of the city. The restoration operation, which lasted five years, aimed to keep the original look unaltered, and the Zintek technicians ensured their presence all throughout the works, from the initial design to the elaboration of estimate costs, as well as with direct support in the building site during the installation of the various elements.

When arriving in Venice, no visitor can ignore the architectonic structure of the Molino Stucky Hotel: its construction was commissioned as far back as 1882 by mechanic, designer and visionary Giovanni Stucky. The new construction was to be built on top of the remains of an ancient cloister. The structure experienced a glorious first half century of life, registering record-shattering numbers: continuous, 24/24 production, with more than 1,500 workers in charge of producing 250 tons of flour, pasta and biscuits on a daily basis. It was also the first production plant in the area to use electricity and cutting edge machinery. Today, the Molino Stucky building hosts the Hilton hotel and conference center.

The roofing solutions were a particularly delicate topic: the process involved looking at both materials and construction techniques used in typical Venetian architecture. This led to the discovery that, ever since the beginning of the twentieth century, pure zinc was heavily used in the city for the construction of drainpipes and decorative elements, including those of the Molino Stucky.

The desire to restore this custom while simultaneously using a modern material, led to the selection of zintek® titanium zinc rolled products, the heir apparent to zinc: this material features the same grey hue, which combines perfectly with the typical bricks of the Molino Stucky, while offering the same moldability and increased resistance.

The human component played a key role in understanding the past and consequently in adapting the product to the existing heritage context, prioritizing qualitative factors, rather than quantitative ones.

THE HUMAN COMPONENT AS KEY FACTOR

Excerpt from the interview with Renata Codello

General Secretary of the Giorgio Cini Foundation

From smokestacks to sustainability: in Murano, Le Conterie become light and sustainable

Our journey now leads us to Murano, where we will discover the composite requalification of Le Conterie, the sustainable urban restoration of a historical industrial area extending over a surface of 22,000 square meters.

Over the course of the centuries, the ”glass island” has developed a unique housing model, featuring one-of-a-kind buildings that include both residential structures and furnaces. The Conterie complex, dedicated to glass production since 1830 and the ancient production site of pearls and beads (known as “conterie”), was built at the end of the nineteenth century.

The project aimed to adapt the restoration to the housing use of the structure, with particular attention to relations with the surrounding urban texture, while also conserving the memory of the industrial settlement.

This restoration project reinstated a student housing structure, a residential complex, craftsmanship and commercial buildings, an extension of the museum and a hotel.

Particular attention was paid to the selection of the materials, in order to preserve the tight link between the new buildings and pre-existing constructions: salvaged bricks were used to replace missing wall portions; full new bricks were made by hand; slaked lime mortar and thinly ground terracotta were used to plaster the joints; sanded fair-faced bricks were used to reinforce the existing façade. And, of course, the project used roofing solutions made of zintek® titanium zinc rolled products.

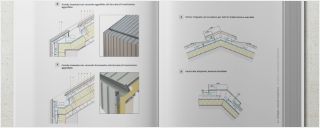

Here, the harmony of the shapes combines aesthetic beauty with resistance. The regular geometries, where an alternation of empty and full spaces lightens the complex, were emphasized thanks to roofing solutions built with the technique known as “German” or “Belgian”, involving the use of batten joints. This is where the flexibility of zintek® truly stands out.

THE IMPROVEMENT BROUGHT BY ZINTEK

Excerpt from the interview with Renata Codello

General Secretary of the Giorgio Cini Foundation

From Venice to the world: the Vatican Chapel, where the daily reality of Zintek becomes international art

Our journey comes to its end in the Giorgio Cini Foundation, on the marvelous island of San Giorgio. The wood of the island hosts the permanent exhibit of the Vatican Chapel built by Zintek with the architect Sean Godsell for the pavilion of the Holy See, during the 2018 Venice Architecture Biennale.

The first participation of the Holy See in the Architecture Biennale materialized in the form of ten chapels designed by ten great architects in the wood of the island of San Giorgio, which was transformed into a metaphor for a labyrinth.

In this dialogue with the world of art, the Vatican Chapel built by Zintek is a tower with a steel load-bearing structure and fully clad in zintek® titanium zinc.

The four sides of the tower open up to reveal the altar and, when observed from above, the vertical doors of the chapel form a cross. The architect intended the chapel to be a peaceful and safe place, which invites the visitor to contemplate, meditate and reflect on one’s self.

The union between the architect Godsell, the Holy See project and Zintek bears pioneering meaning.

This project explored new horizons and possibilities. The qualities of zintek® reveal their features in a manufact where the versatility of the material transforms into versatility of thought and concept. From conservation recovery to pure art, in a symbolic dialogue expressing affinity between technology, artistic project and high performance materials.

A RARE ALCHEMY

Excerpt from the interview with Renata Codello

General Secretary of the Giorgio Cini Foundation